3528 high-pressure lamp with

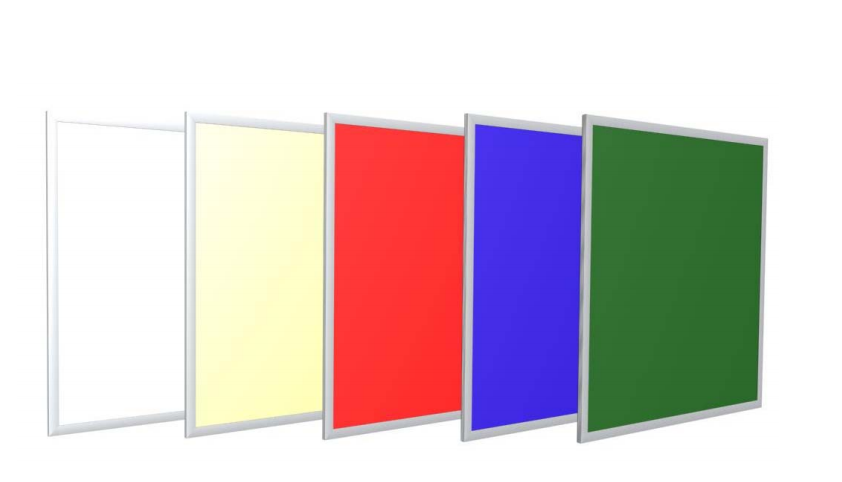

3528 high-pressure lamp with 300 * 1200mm Panel Light

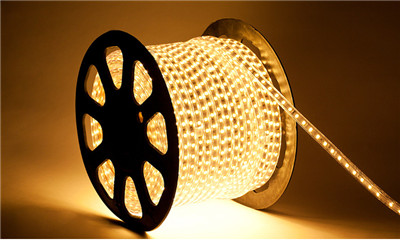

300 * 1200mm Panel Light 5050 RGB lights with high pressure

5050 RGB lights with high pressure 5252 color lights with high pressure

5252 color lights with high pressure Glue deep waterproof lights

Glue deep waterproof lights Single-lamp color temperature lights

Single-lamp color temperature lights 5050 color temperature lights

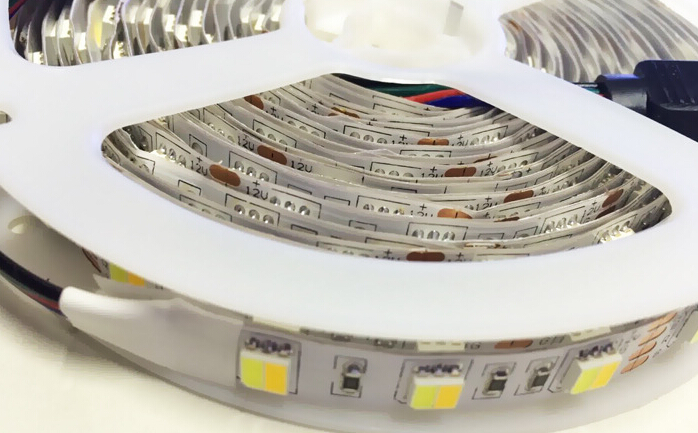

5050 color temperature lights 5050 60 lights filling plastic

5050 60 lights filling plastic 5050 60 lights casing

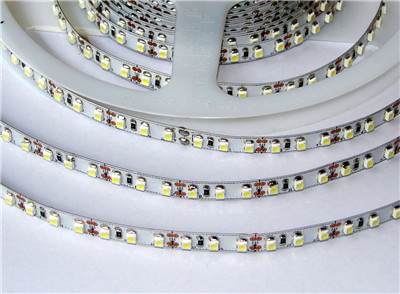

5050 60 lights casing 3528 240 Lights

3528 240 Lights 5050120 Lights

5050120 Lights 5050 RGB low-voltage lights

5050 RGB low-voltage lights 3528120 Lights

3528120 Lights 5050 Blu-ray high-voltage lights

5050 Blu-ray high-voltage lights 5050 High-voltage lights

5050 High-voltage lights 600mm * 600mm panel light

600mm * 600mm panel light RGB Panel Light

RGB Panel Light Color temperature adjustment panel light dimmer

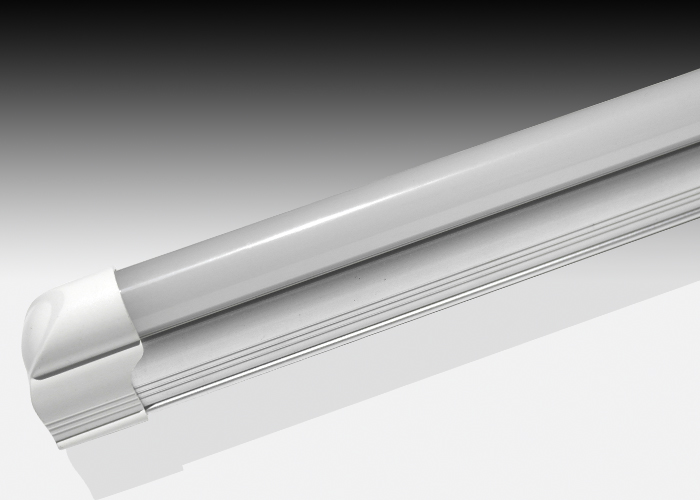

Color temperature adjustment panel light dimmer T8 single tube

T8 single tube T5 Integration lamp

T5 Integration lamp SMD5050 Epoxy lights

SMD5050 Epoxy lights 240 mm* 16mm Round panel lights

240 mm* 16mm Round panel lights Round color panel lights

Round color panel lights

The beginning of reform and opening, China with low labor costs and favorable investment conditions, as the best destination in Europe and America, Japan and South Korea and other economies, the low end of the industrial chain transfer processing and manufacturing sectors. LED industry is also true, by developing export-oriented economy foundry, forming a plurality of LED industrial zone Pearl River Delta, Yangtze River Delta, Delta and other coastal areas of Fujian.

Currently, the foundry is still one of the main development pattern of China's LED industry. With LED product prices, market competition, brand enterprises to reduce costs, domestic demographic dividend disappearing raw material costs continued to rise, the development of the foundry business has been severely constrained. Faced with changing economic environment, LED OEM enterprises to actively strategic transformation, or they will be eliminated.

OEM of the crisis and the machine

LED foundry model mainly processing, OEM, ODM modes. That original equipment manufacturers OEM, commonly known as OEM; ODM is based on OEM, or take part in research and development and product design. Currently, the domestic LED industry OEM OEM-based. Data show that the proportion of China's exports of OEM LED products reach more than 80%.

Foundry can help brands and manufacturers to achieve win-win cooperation, the brand, technology and cost control, combining the advantages of cheap labor. OEM business transformation to become the traditional lighting LED lighting, one of the main ways to participate in most of the domestic LED enterprises in global competition. Early NVC, Foshan Lighting, the United States and other traditional lighting companies have invariably adopted the cut LED lighting OEM mode, for these channel-winning traditional lighting companies, the biggest advantage is obviously not production processes.

In March 2010, established Absen lighting division, defined its global LED lighting professional OEM / ODM integrated service provider positioning, choice to make as an important foundation for the start of the lighting industry.

"Many domestic SMEs to focus on doing OEM business, mainly forced to survive the pressure. OEM orders is relatively stable, shorter operating cycle, cash on delivery, there is too much financial pressure and inventory. Foundry just need to focus on R & D production areas, so the brand requires a huge upfront investment, high-profit, high risk. "A senior industry source said.

By energy conservation policies, a sharp rise in global demand for LED end product. International lighting giants, domestic and cross-border corporate brand LED manufacturers, have entered the field of LED lighting to expand production capacity to snatch market, which for the OEM to provide more opportunities for development.

OEM brand operators an effective way to quickly seize the market. To have a solid financial strength, strong brand influence, advanced technology research and development and rich experience in brand operation of the market operators, through the OEM to integrate the product advantages can be realized in a short time to maximize productivity and product diversification . Such as Philips, Osram and GE most of the products are produced by OEM out, Shanghai Yaming, the sun lighting, to fly, lighting, Li Bite it has for Philips Lighting OEM through energy-saving lamp series.

As a "smile curve" on the lowest value-added manufacturing sector, labor cost difference is the main source of profit for the foundry business, because customers will pay for the higher labor costs in accordance with foundry prices. But with the domestic labor costs, raw material costs continue to increase, the gradual disappearance of the demographic dividend, LED foundry business can only maintain our earnings by the amount.

The world's most influential manufacturing plant Foxconn, is the best at mass production, control labor costs and material costs, are now starting to transition and take the road of independent brands and the use of machinery production. Thus, the situation is more difficult for small and medium manufacturing enterprises. An industry source said: "Before the big brands for processing, profit is OK, but with the increasingly fierce price war, the company will price the weight of brand despicably low, and profits increasingly thin, the slightest mistake It will lose money. "

In this regard, intellectual property Professor Xu Chunming, vice president of Shanghai University, said that China's OEM business must be transformed, because the foundry profit model that low labor costs, but in recent years, China's labor costs by 10% -20% annually increase the proportion of China's LED foundry industry squeezed profit margins. Our LED enterprises to achieve from a cost-driven to innovation-driven transition to independent brand.

OEM and own brand parallel

LED industry, the middle chip packaging technology and innovation in the field is the main driving force; in the downstream lighting applications, brands and channels is often the core competitiveness of enterprises. As neither the technology, nor the brand and channels of LED manufacturing enterprises, can only survive by working meager profit, which is not conducive to long-term development.