3528 high-pressure lamp with

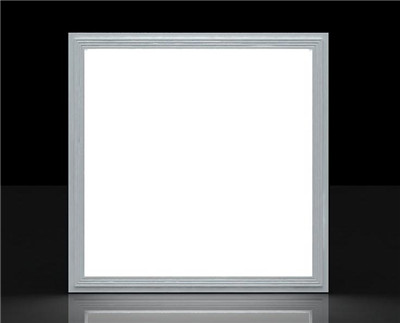

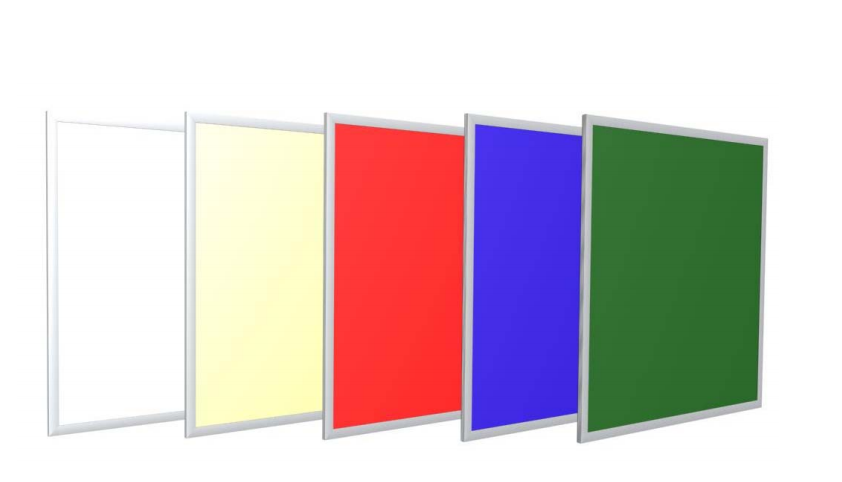

3528 high-pressure lamp with 300 * 1200mm Panel Light

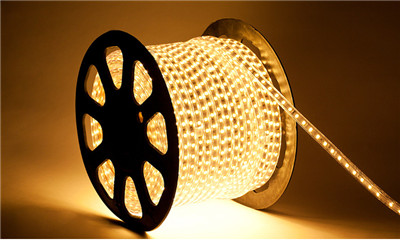

300 * 1200mm Panel Light 5050 RGB lights with high pressure

5050 RGB lights with high pressure 5252 color lights with high pressure

5252 color lights with high pressure Glue deep waterproof lights

Glue deep waterproof lights Single-lamp color temperature lights

Single-lamp color temperature lights 5050 color temperature lights

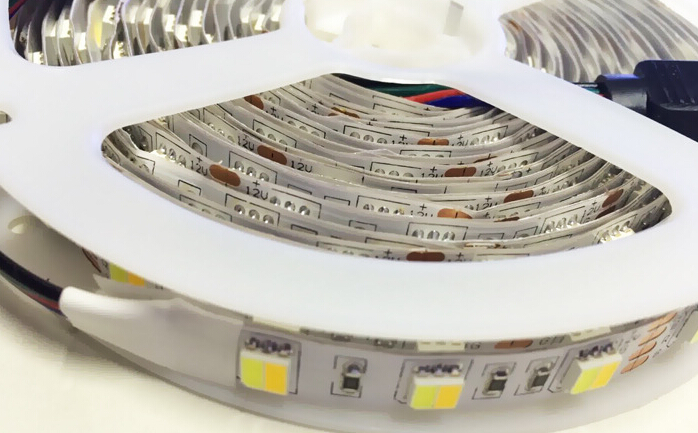

5050 color temperature lights 5050 60 lights filling plastic

5050 60 lights filling plastic 5050 60 lights casing

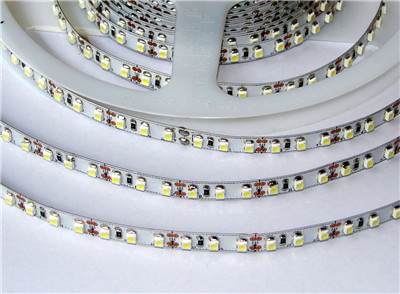

5050 60 lights casing 3528 240 Lights

3528 240 Lights 5050120 Lights

5050120 Lights 5050 RGB low-voltage lights

5050 RGB low-voltage lights 3528120 Lights

3528120 Lights 5050 Blu-ray high-voltage lights

5050 Blu-ray high-voltage lights 5050 High-voltage lights

5050 High-voltage lights 600mm * 600mm panel light

600mm * 600mm panel light RGB Panel Light

RGB Panel Light Color temperature adjustment panel light dimmer

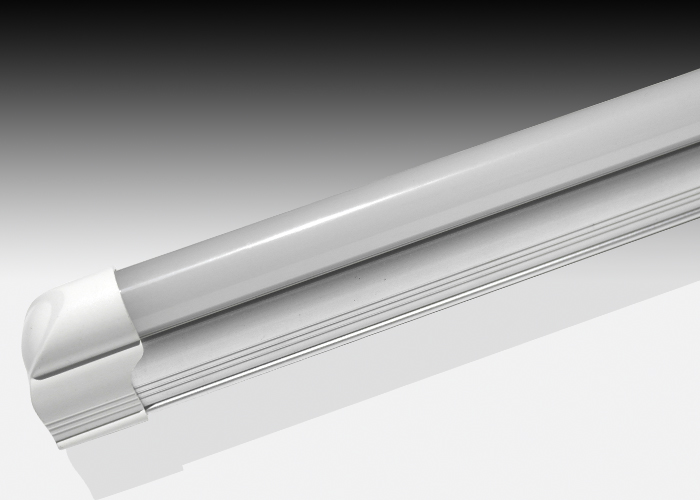

Color temperature adjustment panel light dimmer T8 single tube

T8 single tube T5 Integration lamp

T5 Integration lamp SMD5050 Epoxy lights

SMD5050 Epoxy lights 240 mm* 16mm Round panel lights

240 mm* 16mm Round panel lights Round color panel lights

Round color panel lights

First, what is EOS?

EOS is Electrical Over Stress acronym refers to all electrical overstress. When the external current or voltage exceeds the device's maximum specification condition, device performance will be weakened or even damaged.

EOS usually created

1. Power Supply (AC / DC) interference, power supply noise and over-voltage.

2. Since the test program switching (hot switching) due to transient current / peak / low frequency interference. The process duration may be a few microseconds to a few seconds (and possibly a few nanoseconds), similar to the damage and ESD damage is caused by a short pulse EOS.

3. Lightning.

The transient test program switch caused / glitch / glitches.

5. Test poorly designed, for example, in the device has not been powered on or has exceeded its operational ceiling case of transmitting the test signal to the device. Another example of the power supply to the device before the addition of the test signal, or exceeds the maximum operating conditions.

6. The pulse signal interference from other devices, the pulse transmitted from other devices.

7. inappropriate work steps, workflow is not reasonable

8. ground bounce (due to take place fast enough to cause the current to cause high voltage converter)

Second, what is ESD?

English Electrical Static Discharge ESD is shrinking, Chinese Buddhism and electrostatic discharge. The charge is transferred from one object to another object. Static electricity is an objective natural phenomenon, a number of ways, such as contact, friction and so on. Static electricity is characterized by high voltage, low power, low current and time is short features. The body's own action or contact with other objects, separation, friction or induction and other factors that can generate thousands of volts or even thousands of volts of static electricity. Electrostatic serious harm in a number of areas. Friction from static electricity and the human body is the electronics industry in the two hazards. The main measures in the production process of electrostatic protective electrostatic leakage, dissipation, and, moisturizers, masks and ground. Human electrostatic protection system mainly anti-static wrist band, ankle band, uniforms, shoes and socks, hats, gloves or finger etc., with static leakage, and the mask function. ESD protection is a long-term system engineering, errors or omissions in any part, will lead to the failure of the ESD protection.

Third, the contrast difference

EOS

ESD

Typically, generated by the power supply and test equipment

ESD belong EOS exceptions, limited energy, caused by electrostatic charge

Event duration in microseconds seconds. (And possibly nanoseconds)

Event duration in pico seconds to nanoseconds

The phenomenon of corruption include wire melting, heating, high power, Latch

Its visibility position is not strong damage difficult to find,

EOS short pulse damage looks like ESD damage

Usually results in damage to the transistor level.

Fourth, static protection

1. Set the static region

Description: The production site set static sensitive areas, and to do obviously warning 使到 everyone can pay attention to the site.

2, static region within Notes

a. Operators should wear anti-static wrist strap should wear anti-static clothing, shoes, scarves, chair should cover anti-static sets. (One end in contact with the human body, and the other end is connected with the ground)

b. There may be placed within the area to be posted PBA anti-static cloth, and to join anti-static grounding buckle.

c. all the items in the static region electrostatic vessel must not exceed 100V static area should be anti-static materials, if the electrostatic voltage electrostatic goods within the region of more than 100V, which is should be used to eliminate surface electrostatic ion fan. NOTE: Do not place items unrelated to production activity in the anti-static area.

3. Environmental humidity should be 50% to 60% left