3528 high-pressure lamp with

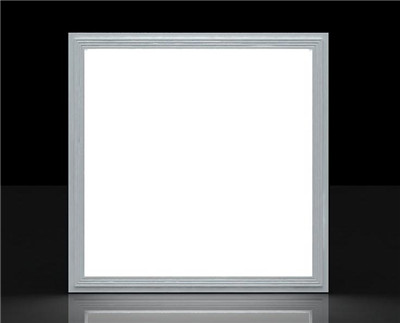

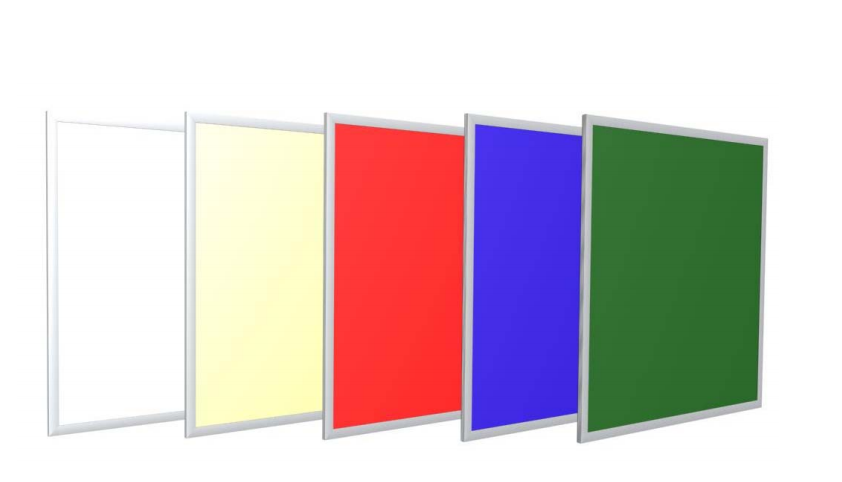

3528 high-pressure lamp with 300 * 1200mm Panel Light

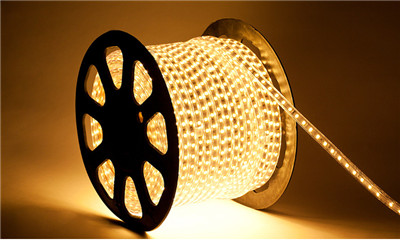

300 * 1200mm Panel Light 5050 RGB lights with high pressure

5050 RGB lights with high pressure 5252 color lights with high pressure

5252 color lights with high pressure Glue deep waterproof lights

Glue deep waterproof lights Single-lamp color temperature lights

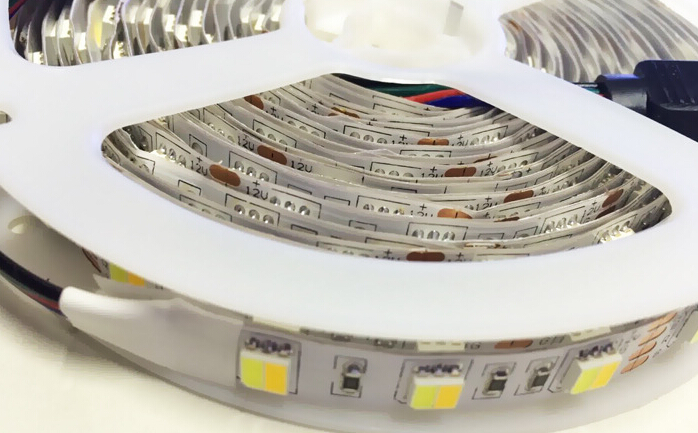

Single-lamp color temperature lights 5050 color temperature lights

5050 color temperature lights 5050 60 lights filling plastic

5050 60 lights filling plastic 5050 60 lights casing

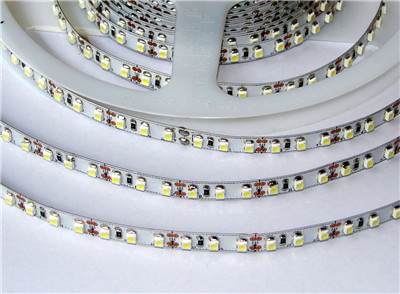

5050 60 lights casing 3528 240 Lights

3528 240 Lights 5050120 Lights

5050120 Lights 5050 RGB low-voltage lights

5050 RGB low-voltage lights 3528120 Lights

3528120 Lights 5050 Blu-ray high-voltage lights

5050 Blu-ray high-voltage lights 5050 High-voltage lights

5050 High-voltage lights 600mm * 600mm panel light

600mm * 600mm panel light RGB Panel Light

RGB Panel Light Color temperature adjustment panel light dimmer

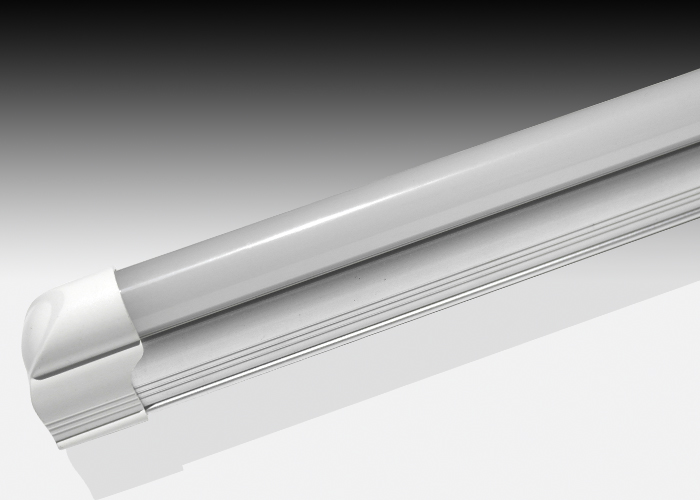

Color temperature adjustment panel light dimmer T8 single tube

T8 single tube T5 Integration lamp

T5 Integration lamp SMD5050 Epoxy lights

SMD5050 Epoxy lights 240 mm* 16mm Round panel lights

240 mm* 16mm Round panel lights Round color panel lights

Round color panel lights

Just a symbol of human civilization, and LED light source 21 is a new century, LED very consistent with modern concepts: green, health, environmental protection, energy saving, long life. Although LED incandescent lamp has a stronger adaptability and life compared to, but in the application and use should be noted that the following requirements to ensure LED stable, long-term work properly.

First, the voltage and current

1. Do not recommend parallel use LED, because even the same model, same batch of LED operating voltage has some differences, unless good current sharing circuitry.

2. When you install super bright white LED, have anti-static facilities, because by the electrostatic damage super bright white LED even when the naked eye can not see, will reduce service life.

3. If the LED operating voltage 0.1V, operating current may change it around 20mA. Under normal circumstances the use of current limiting resistor in series, you can also use a simple constant-voltage circuit, the purpose is to achieve automatic limited pressure limiting to prevent damage to LED.

4. ordinary LED peak current is 50 ~ 100mA, reverse voltage at 6V, when the LED application design of the circuit to the attention of the peak voltage and current do not exceed this limit. (Excluding special and high power) when the peak voltage of the circuit is likely to damage the high LED.

Second, the welding conditions

1. soldering iron:

Hand soldering iron welding, requires less than 25W (maximum of 30W) of iron, and iron temperature must be kept no higher than 300 ℃, 260 ℃ is generally recommended in order. Soldering time not more than three seconds.

2. Dip soldering:

Dip soldering tip temperature requirements of 260 ℃, dip soldering time not more than five seconds, the Baptist welding position at least 2 mm from the gel.

NOTE: After welding, the temperature of LED products declined again be handled carefully when to room temperature. Do not use hard objects and sharp objects scratch, Sassafras, touch, squeeze, pressure LED.

Third, the installation method

1. Note that the arrangement of the perimeter to prevent loading the wrong polarity.

2. Do not get too close and the heating element.

3. Do not install LED pin in the case of bending deformation.

4. When installation LED, recommended guide sleeve positioning.

5. In the welding temperature back to normal before, do not let the LED vibration or external forces.

Fourth, cell cleaning

The following should be carried out after welding program for cleaning.

1. Cleaning Solvent can use Freon TF or alcohol, or other similar solvents.

2. Clean up the temperature control in 30 seconds or 3 minutes up to 50 ℃ 30 ℃, the temperature too high.

3. Elected to use ultrasonic cleaning, do not exceed the maximum power of 300W.

Note: When using chemical cleaning colloid pay attention, because as will the colloid surface with trichlorethylene, acetone, etc. damage. You can use alcohol wipe, dipping, but not more than three minutes.

Fifth, the temperature characteristic

The temperature characteristics of the LED, the temperature rise 5 ℃, flux decline of 3%, to note that LED working temperature and storage temperature regardless of winter or summer of use.

1.LED LAMPS minimum operating temperature of -25 ℃ up to 85 ℃, the minimum storage temperature is -40 ℃ up to 100 ℃.

2.LED display screen minimum operating temperature of -20 ℃ up to 70 ℃, the minimum storage temperature of -20 ℃ up to 85 ℃.

3. Outdoor LED Light (OUT-DOOR LED LAMPS) the minimum working temperature of -20 ℃ up to 60 ℃, the minimum storage temperature of -20 ℃ up to 70 ℃.

Six other considerations

At a high temperature bare SMD LED, do not squeeze its part epoxy or other sharp or hard objects scratch, because Epoxy is very fragile, easily damaged.