3528 high-pressure lamp with

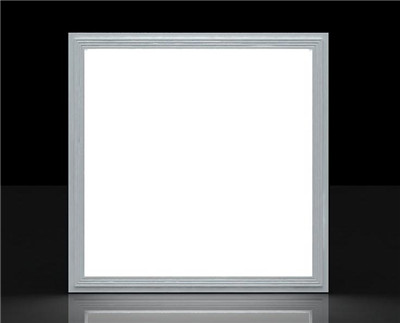

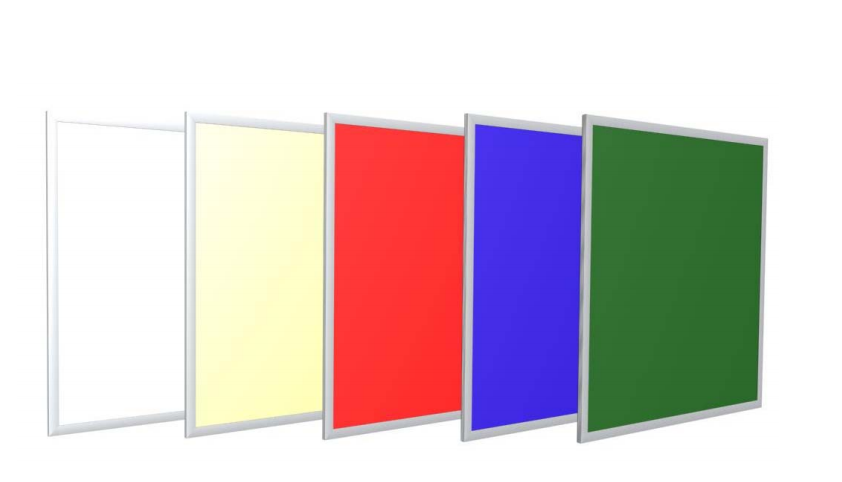

3528 high-pressure lamp with 300 * 1200mm Panel Light

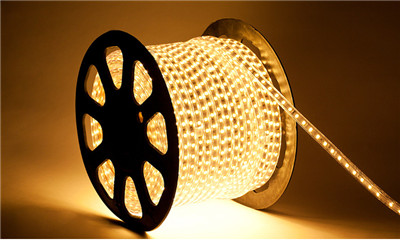

300 * 1200mm Panel Light 5050 RGB lights with high pressure

5050 RGB lights with high pressure 5252 color lights with high pressure

5252 color lights with high pressure Glue deep waterproof lights

Glue deep waterproof lights Single-lamp color temperature lights

Single-lamp color temperature lights 5050 color temperature lights

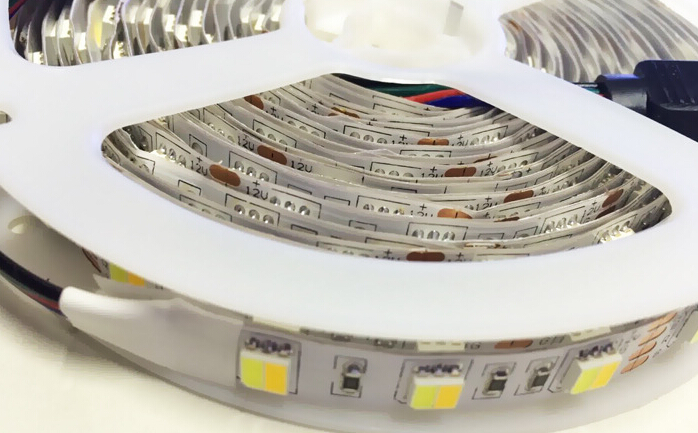

5050 color temperature lights 5050 60 lights filling plastic

5050 60 lights filling plastic 5050 60 lights casing

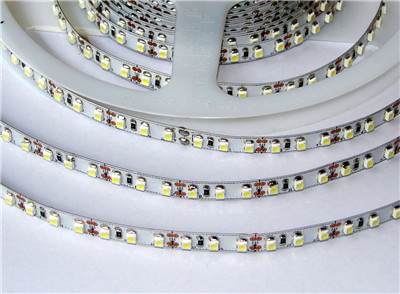

5050 60 lights casing 3528 240 Lights

3528 240 Lights 5050120 Lights

5050120 Lights 5050 RGB low-voltage lights

5050 RGB low-voltage lights 3528120 Lights

3528120 Lights 5050 Blu-ray high-voltage lights

5050 Blu-ray high-voltage lights 5050 High-voltage lights

5050 High-voltage lights 600mm * 600mm panel light

600mm * 600mm panel light RGB Panel Light

RGB Panel Light Color temperature adjustment panel light dimmer

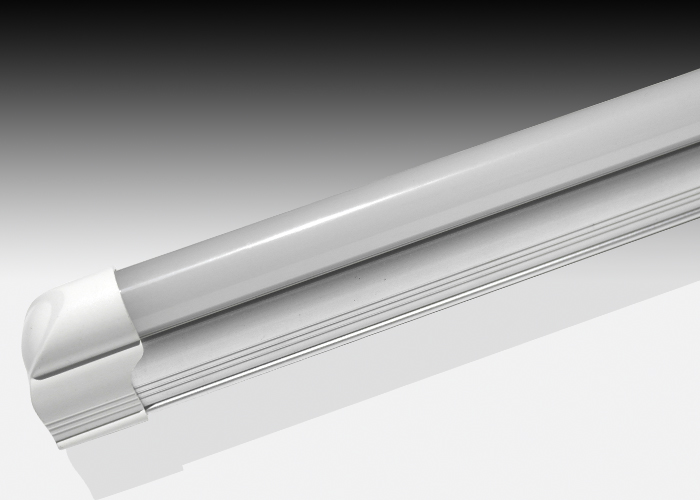

Color temperature adjustment panel light dimmer T8 single tube

T8 single tube T5 Integration lamp

T5 Integration lamp SMD5050 Epoxy lights

SMD5050 Epoxy lights 240 mm* 16mm Round panel lights

240 mm* 16mm Round panel lights Round color panel lights

Round color panel lights

Now when purchasing LED light source inquiry usually ask what chip, familiar with some of the light will ask the chip size, and then based on the same chip the same housing and factories promise warranty time to phase in at least Compare prices, but the same chip different package, the quality of this chip out of the finished package will be a big difference.

Below said about what specific differences:

1, the chip radiated power level difference:

Xiamen Sanan's chip, for example, S-23BBMUP-C *******, chip size 23X10mil, this core has four radiation power levels (@ 20mA), the higher the radiation power, made lamp beads The brighter.

D24 radiated power 26-28mW

D25 radiated power 28-30mW

D26 radiated power 30-33mW

D27 radiated power 33-36mW

D24 and D27 of the radiant power difference 8mW, ie, the same size chip, lamp beads made of different brightness, a lot of difference, need to understand the chip radiation power levels.

In fact, the chips currently on the market are graded, the town a lot of light packaging factory goods are clearly divided into A, B goods. Different product views are different prices, of course, many took the unfamiliar may also pay the price of the product B product A product.

2, lamp beads scaffold difference:

There are currently on the market aluminum frame, brass stand, copper stents, stent cheapest aluminum, copper stand the most expensive, the price difference of ten times. Even the copper bracket, silver prices also have high and low points, the market is generally referred to as a good stand, mostly made of silver-plated brass.

The difference between aluminum frame with copper frame is very easy to distinguish (to get hands inside a weigh light is aluminum), while now some factories do not iron frame of aluminum is also useful, of course, no matter what stand, take a lamp beads to make Destructive tests on the outcome, the number of procurement will be done those too, especially some product procurement, even light beads did not see what it was like, only to see the finished product.

In fact, I think a lot of manufacturers of business encountered such a situation is also very depressed, seemingly the same product, but is a big difference in raw material prices, and customers also feel other people the same price lower than you, the quality is the same (warranty Two years, a situation is not a problem within two years, or slightly protruding out of the question can not count, another case is often a bad product, but also acknowledged the warranty, this option should be slightly more expensive point of no problem or often the problem, repair warranty it?).

3, the chip size difference:

The chip size is generally reported based mil, if not high-powered measuring microscope, it is difficult to distinguish between general, the greater the brighter chip, we can compare the chip size by calculating the chip area, such as 23X10, the chip area is 230 square mil, It is a good way to distinguish chip size chip area.

Such as wafer 35 (that is 35 * 35MIL), is now pushing wafer chip 32 * 32, the town market to be relatively random number, say two years ago, many packaging factory wafer 38 is gone, but now there are packaging factory We are still selling crystal element 38; this year's cut-off push Epistar 35 32 these dimensions, but there are still a lot of packaging factory still sell 35 (also a case might be made of the stock), but we have found that some people fooled some novice, Fudge took Di source is crystal source; we stop at the chip plant chip size ones usually go along with the chip factory, because to continue with the original face out of stock, the other is the stock of goods will be competing not so assured.

4, the wire material differences:

Chip and support is complete with gold wire bonding method in electrical communication with the wire on the market today, two gold wire, gold wire is best, according to the thickness of the gold is divided 0.7,0.9,1.0,1.2 etc., the more gold thick, lower heat set, the longer the life, to ask what all the gold wire material and diameter.

Prices here vary widely, but many town pin LED light source is actually not the manufacturers, but manufacturers take the goods to sell, he could take several packaging plants to sell, there are tricky here, the town is not a lot of people take light test, some people like to keep the prices down, he said, such as wafer 8 hair one, you say okay 7 twenty-five, he said to see the amount of it, you may get the last few give you seven twenty-five, but the inside is alloy wire or gold wire will be suspect (of course, this town has formed a habit), they sell basically no one to look for trouble, because no one managed this.

Note this: the wire with gold alloy wire than at work more easily broken, which is easier to die light, thick enough gold wire can withstand 60,000 hours, and the wire may be less than 30,000 hours, plus other packages factors, power factors, environmental factors shell heat factor and use the finished lamp life even shorter.

5, the phosphor difference:

White light beads with blue chip plus ** phosphor made of phosphor divided aluminate and silicate, aluminate outperforms silicate, aluminate most representative is YAG, YAG stable performance low lumen depreciation, silicates poor chemical stability itself, but the brightness is higher than YAG, wants stable performance products, can not be called high brightness fooled, this is a big problem.

Phosphor quality directly determines the source of light and color purity with durability, some light Why is a period of time with the packaging technology changed color with the material, but off cause.

6, glue difference:

Phosphor is to glue and after stirring at the point on the chip, glue affect the quality of the light fades and color drift, poor glue for a long time will be yellow, light increase, the glue is jelly.

Some packaging factory packaged products glue bead seal to the lamp lens, while how also installed equipment outdoor products when the lens holder is not in place, when this situation occurred two years ago, now it is less than, but still there .

7, color separation, the partial pressure of the spectral specifications:

Separation: is the color temperature binned as 3200K-3350K is a file, the regular packaging factory will provide the color temperature of the BIN code, color temperature sub-file as small as possible, the color temperature sub-file size, color to make the source light consistency .

Partial pressure: is the chip's voltage binning, such as 3.0V-3.15V, the light source is a series-parallel connection, the voltage binning control within 0.15V, uniform current distribution so light, help to improve the life of the light source.

Splitting: that light bead brightness binning, sub-file or have lumens light intensity binned used for lighting, preferably lumens bins. Recommend purchasing LED, or in luminous efficiency as the basis, high-efficiency products, energy saving, long life before.